In order not to shut down the entire production process in the event of a fire, a manufacturer of pharmaceutical-optical devices commissioned Lehmann Engineering GmbH with the networking of a fibre optic ring made of glass. Aim was the integration of an “emergency stop” to stop only the hazardous area and the directly affected production facilities in the event of a malfunction.

Task

Task of the Lehmann Engineering GmbH was the development of a reliable solution, which in the case of malfunctions (for example fire risk, leakage, maintenance, etc.) only stops the affected units and not the entire production area. For this purpose, the entire production – from the tank farm via several production facilities to waste disposal – was networked with a glass fibre optic cable ring. The goal is to keep production downtime as low as possible in order to resume operations as quickly as possible and to achieve greater profitability at the same safety level.

Solution

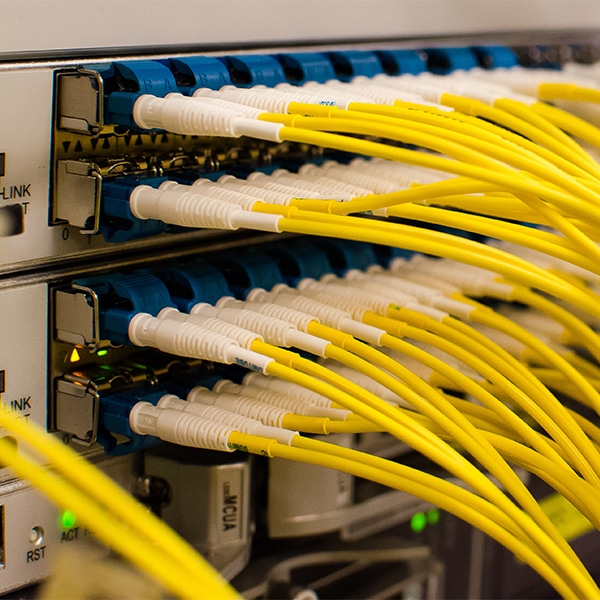

With the integration of this particular “emergency stop”, all production sections can be monitored and controlled from multiple operating stations. Siemens switches and a redundancy manager ensure that the data always stays in the flow, regardless of the direction.

Thanks to the fail-safe Siemens S7-416F control system, the signal packets are transferred to the Remote IO (RIO) stations and controllers of the package units in the subsystems or production plants. This ensures error-free and reliable transmission of all security-relevant data. If a fault occurs in one area of the production cycle, a message is immediately sent to all other operating stations. An emergency stop button solely places the endangered environment in a safe stop state. The explosion-hazardous areas such as SIL1 shutdowns are also integrated, while all other areas can continue to work.